MCCQ18F.0 type pulse dust collector

Classification :

|

MCCQ18F.0 pulse dust collector parameters |

|

|

Filter area (㎡) |

18 |

|

Filter wind speed (m/min) |

1.2~2 |

|

Processing capacity (m³/h) |

1296~2100 |

|

Quantity of filter bags (strips) |

24 |

|

Quantity of pulse valves (pieces) |

2 |

|

Fan power (Kw) |

3 |

|

Air consumption for dust cleaning (m³/min) |

0.1~0.3 |

|

MCCQ18F.0 pulse dust collector parameters |

|

|

Filter area (㎡) |

18 |

|

Filter wind speed (m/min) |

1.2~2 |

|

Processing capacity (m³/h) |

1296~2100 |

|

Quantity of filter bags (strips) |

24 |

|

Quantity of pulse valves (pieces) |

2 |

|

Fan power (Kw) |

3 |

|

Air consumption for dust cleaning (m³/min) |

0.1~0.3 |

Environmental protection is a national policy of our country. The increasingly serious environmental pollution has seriously affected the normal work and life of each of us. As society pays increasing attention to the living environment and life safety. Environmental protection requirements are also constantly increasing in various places. Requirements for dust emissions are also becoming increasingly stringent. The function of the dust removal device is to reduce the concentration of dust emissions and protect the atmospheric environment. The high-voltage pulse backflush dust collector is an efficient dust removal device. The dust generated during the production process is purified by the pulse dust collector and the dust concentration emitted into the atmosphere is basically controlled at 15-20mg/m³, which can fully meet the 30mg/m³ stipulated by the national environmental protection department.

1. Conditions for use of dust collector

Supply power

1. Input voltage AC220V±20% 50HZ

2. Output voltage DC24V

3. Output current 1A

Pulse valve parameters

1. Output pulse interval adjustment range 1-30s

2. The output pulse width adjustment range is 0.03-0.2s

Usage environment

1. Working environment temperature of dust bag: -25℃ ~+120℃

2. The relative humidity of the air does not exceed 85%

3. Working pressure 0.2Mp~0.3Mp

2. Structure and working principle of pulse bag dust collector

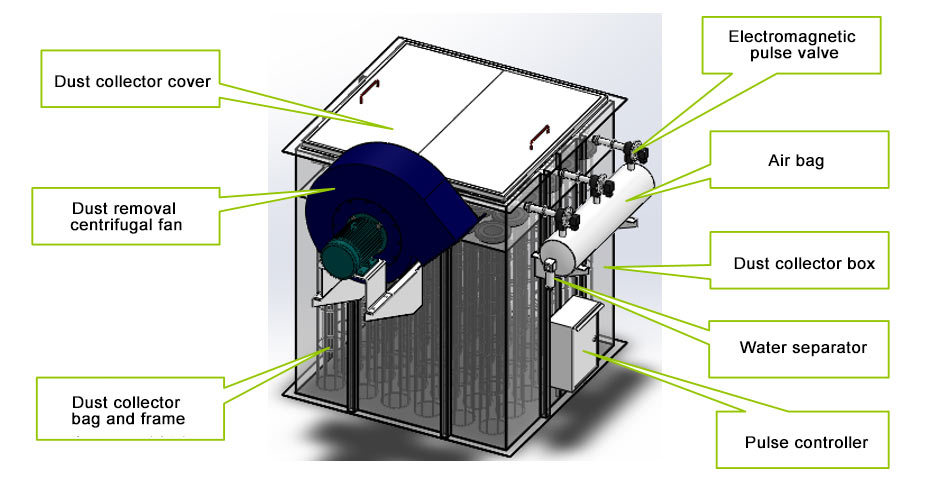

1. Pulse bag dust collector structure

1. The upper cover is composed of a cover plate and a pressing device;

2. The dust removal box is composed of dust removal bag, dust removal frame, flower hole plate, venturi tube, box body, etc.;

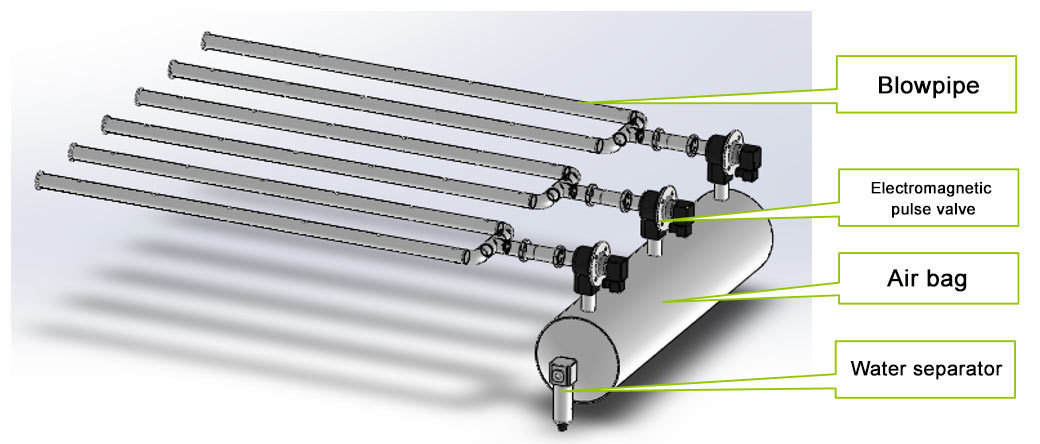

3. The pulse injection system consists of pulse controller, electromagnetic pulse valve, air bag, injection pipe, etc.

Pulse injection system

The compressed air used for dust cleaning in the pulse dust collector enters the air storage bag after being purified by the oil-water separator. When the pulse controller sends a dust cleaning signal to the electromagnetic pulse valve The diaphragm of the electromagnetic pulse valve opens, and the compressed air in the air bag passes through the venturi tube through the holes of the blow tube and enters the filter bag (called primary air). When the high-speed air flow passes through the venturi tube - the ejector At that moment, several times the amount of surrounding air is induced and enters the bag at the same time (called secondary air). Because this and the secondary air form a strong reverse airflow that is opposite to the filtered airflow and is injected into the bag, the filter bag rapidly changes from contraction to expansion to contraction in an instant, and the airflow reverses the effect. Remove the dust adsorbed on the outside of the bag wall one by one.

2. Working principle of dust collector

The dusty air is sucked through the exhaust port by the dust removal fan and enters the dust box from the air inlet of the dust collector. The fine dust is adsorbed on the outer wall of the filter bag through various effects. , the purified air filtered by the filter bag enters the upper box through the venturi tube, and is discharged from the fan outlet. The dust adsorbed on the outer wall of the filter bag accumulates thicker and thicker as time goes by, and the resistance of the dust collector gradually increases. , the amount of gas processed continues to decrease. In order to keep the dust collector in an effective state and stabilize the equipment resistance within a certain range, it is necessary to remove the dust adsorbed on the outside of the filter bag. In the ash removal process, the controller issues instructions to each electromagnetic pulse valve according to the specified requirements, opens the valves in sequence, and injects high-pressure air into each group of filter bags in sequence. As a result, the compressed air in the air bag enters the filter bag (called primary air) through the venturi tube through the holes of the blow tube. When the high-speed air flow passes through the venturi tube - the ejector, the air volume is several times The primary ambient air is induced and enters the bag at the same time (called secondary air). Because this and the secondary air form a strong reverse airflow that is opposite to the filtered airflow and is injected into the bag, the filter bag rapidly changes from contraction to expansion to contraction in an instant, and the airflow reverses the effect. Remove the dust adsorbed on the outside of the bag wall one by one. Since high-pressure air is blown into the bags during dust cleaning in sequence among several sets of filter bags, the dust-containing air that needs to be processed is not cut off. Therefore, during the dust cleaning process, the pressure loss of the dust collector and the amount of dust-containing gas being processed remain geometrically unchanged. This is one of the advancements of pulse bag dust collectors.

Factory

FAQ

Delivery time: about 10-30 working days after receipt of formal order and 40% deposit.

Warranty: 12 months following delivery.

We offer online service 24 hours all day long, including whatsapp, Email, etc. You can contact us at any time, if urgently, please call us.

- RELATED PRODUCTS -

- GET A FREE QUOTE -