ABOUT

JIANCHANG

Process Advantages

Nowadays, most domestic powder silo manufacturers start making raw materials without any processing or simple manual processing. Especially for silo products made at construction sites, most of them purchase materials near the construction site, and the product quality of the raw materials themselves depends on There is no guarantee, and if it is made directly without material pre-treatment, the paint will fall off due to incomplete rust removal in the later stage, resulting in product rust, affecting product quality and seriously shortening the service life.

The raw materials for the overall warehouse production at our company's construction site are purchased and transported back to the company for shot blasting pretreatment. They are sprayed with anti-rust paint and sent to the construction site. The surface treatment is strictly controlled and the anti-corrosion capability is greatly improved. The chip-type cement silo made in the factory is pre-assembled and disassembled. After all parts are shot blasted and sprayed with anti-rust paint, the rust removal completely increases the surface adhesion of the paint and greatly extends the service life of the product. The asphalt station stacks and silos made in the factory are sandblasted as a whole after production, abandoning the original material pretreatment process, so that there are no welding scars on the paint surface and the surface is smoother and more beautiful.

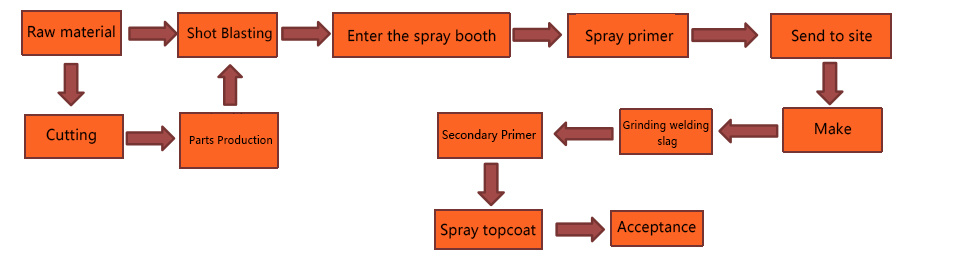

Construction site production overall warehouse flow chart

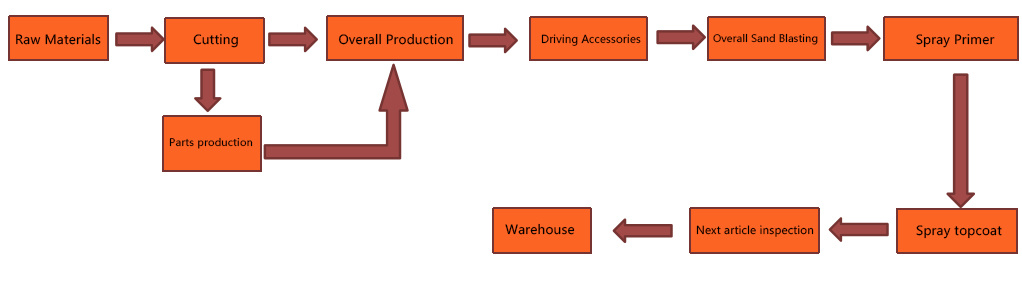

Flow chart for manufacturing integrated cement silos (including asphalt station stacked silos) in the factory

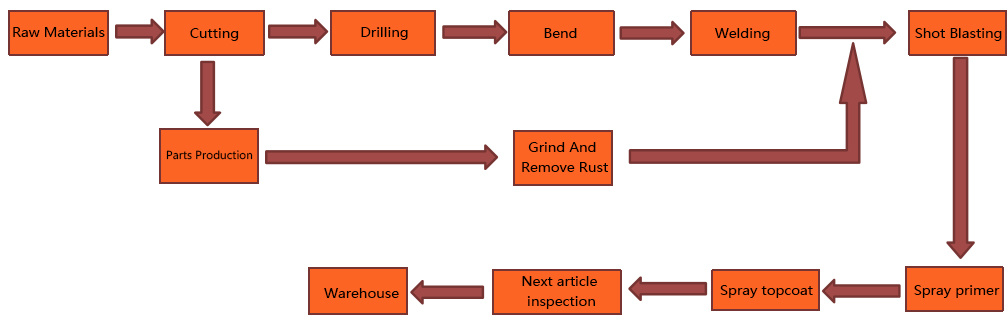

Chip-mounted cement silo process flow chart

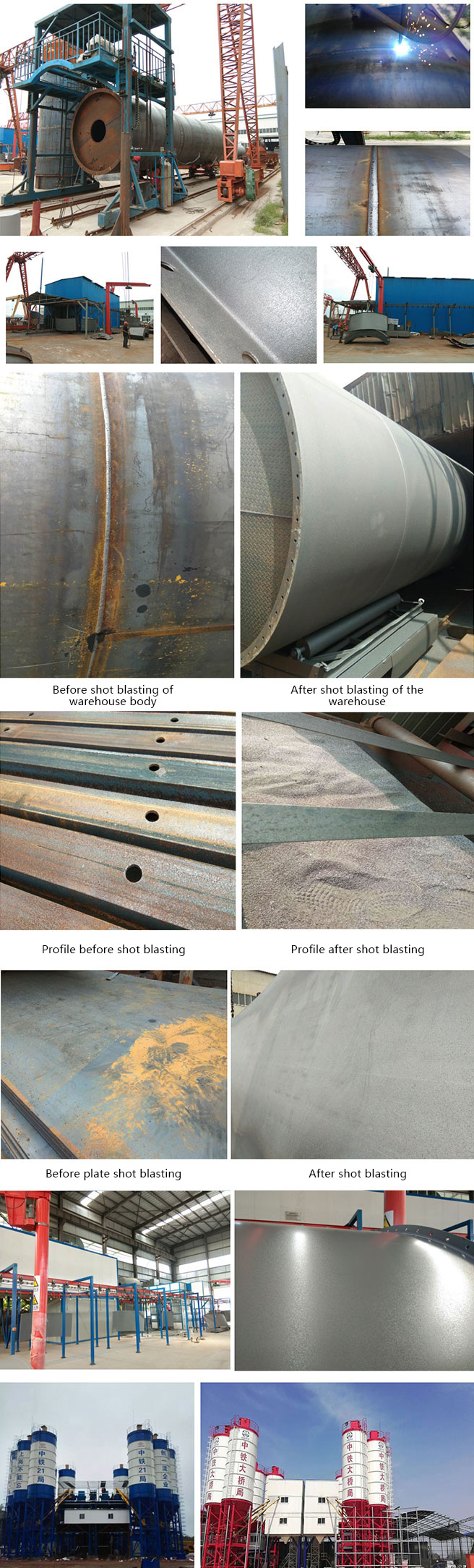

Shot blasting process